Airport board gives nod to contractor to continue to second phase of terminal project

Michael Crumb Aug 21, 2024 | 6:00 am

5 min read time

1,154 wordsAll Latest News, Real Estate and Development, Transportationcommercial real estate

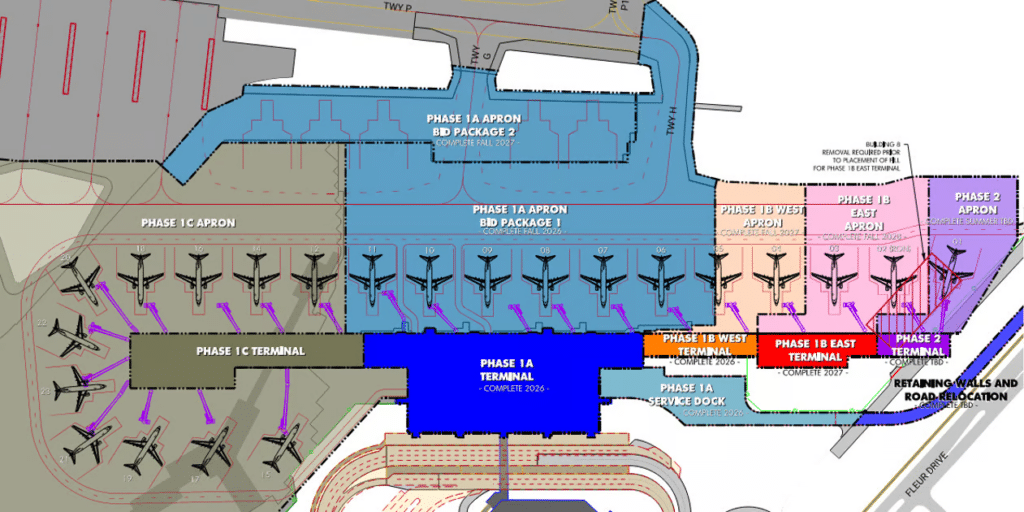

The contractor on phase one of the Des Moines International Airport terminal construction project will continue with another phase of the project, a move that will create about $13 million in savings, the Des Moines International Airport Authority board recently decided.

Last week, the board approved a change order that allows the contractor to move ahead with work on phase 1B, which will add capacity for passengers and airplanes, as it completes the first phase, or phase 1A.

The vote followed the board’s action in July to lower the estimated cost of phase one from $445 million to $425 million, creating a savings of $20 million. That was possible because of bids coming in at or slightly below estimates, said Kevin Foley, the airport’s executive director.

The change order saves another $13 million, he said.

“[Construction] will continue from phase one to phase 1B,” Foley said. “It means the contractor is going to keep right on going, nonstop. They just keep going and the pricing for the work they are doing is already set. If they would leave and we’d have to bring them back, there would be another mobilization charge. The wall [that would otherwise be built and later demolished], the mobilization, the escalation, you wrap all that up and there’s $13 million.”

The total cost of that second phase is $54.4 million.

Foley said subsequent phases will be built as funding becomes available.

The airport is still waiting for word on some federal funding to help cover the costs of the project.

“We’re close,” Foley said. “If we have to borrow, there’s room to do it. [But] we’d rather not.”

Construction on the new terminal is scheduled to be complete with the new terminal beginning operation in early 2027. Demolition of the existing terminal would begin immediately once the new terminal is open, Foley said.

Footings and basement walls for the terminal are being poured, and the project remains on schedule, he said.

The parking garage, which will add 1,100 spaces, bringing to about 2,700 the number of spaces for public parking, is slightly behind schedule, but should be open by spring break 2025.

“And, of course, spring break is one of our heaviest parking demands,” Foley said.

When the new terminal opens, it will increase capacity to handle the growing number of passengers who travel through the airport each year, and capacity to park planes at gates, he said.

The number of gates will increase from 12 to 21 once the project is complete.

The project to add capacity is critical if the airport is to keep pace with the growth the region has seen and is projected to see in the coming years, Foley said.

“To keep up with the market of this area, that’s what is driving this expansion in the first place is the market is growing and we have to stay up with it,” he said. “We’re an economic engine, but if we don’t stay with the market, we become an economic hurdle.”

The airport is seeing 3.3% growth in passenger traffic year over year, a level that was affected by the recent CrowdStrike outage that resulted in a loss of 40 flights, Foley said.

The airport was on pace for 4% growth year over year before the CrowdStrike outage, he said.

But even with the lower level of growth, it is still exceeding Federal Aviation Administration projections of 3% growth year over year.

Through July, nearly 1.85 million passengers have traveled through the airport, according to airport travel statistics. That is up from more than 1.78 million for the same period in 2023.

The Iowa Department of Transportation Bureau of Aviation issued an economic impact study that showed as of 2022, aviation pumped $6 billion a year into Iowa’s economy. The economic impact of the Des Moines International Airport was $752 million, the study showed.

The airport is also having to build a customer service building south of the terminal to accommodate growth, Foley said.

It will serve as a pickup and drop-off point for passengers who are renting cars at the airport.

“We will have to start busing rental car passengers,” Foley said. “The return will be on the south side of the terminal. They will be bussed up if they are departing. As they arrive, if they’re renting a car, they will have to be bussed out. No passenger wants to get on a bus once they arrive. They want to go out and get in a car and leave. That’s what we wanted to maintain. The growth is such we can’t maintain that. We’re just running out of room, mostly to park the [rental] cars up here. We need that space for public parking.”

The airport has also stepped in to help reduce delays caused by de-icing planes during the winter by building a new de-icing facility and working with airlines to bring in an independent company to de-ice planes, Foley said.

De-icing is an airline responsibility, with each airline having their own trucks for de-icing.

Currently, de-icing is done on a 40-acre site, capturing the fluid from the process in a holding tank. That fluid is pumped out and sent to water reclamation for treatment and then disposed of, Foley said.

The new facility is only 10 acres, which will allow for a more concentrated collection of the fluid, which could possibly be sold or recycled and used again instead of being shipped off for treatment, Foley said.

“It’s important environmentally and it’s important to our cost,” he said.

The fluid used for de-icing contains glycol, which can be sold to manufacturers of various products, including paint. If sold, that revenue would come back to the airport’s operation fund, he said.

The airlines have also agreed to contract with an outside company that will bring in 10 de-icing trucks, putting two trucks on a plane at a time, with eight trucks operating at once. That will reduce the amount of time spent on de-icing a plane to about 10 minutes, which can help reduce delays caused by the process, Foley said.

Currently, the airlines have their own de-icing trucks and can de-ice two planes at a time. If a third one needs to be de-iced, the trucks have to refill and the fluid heated before de-icing can begin.

“This last winter, we had delays of up to an hour on the ramp because of de-icing challenges,” he said. “It’s an airline function, but we’ve stepped in to try to facilitate solutions to get rid of that delay.”

Michael Crumb

Michael Crumb is a senior staff writer at Business Record. He covers real estate and development and transportation.