Industry Report: MANUFACTURING

Your QUICK Briefing on One Big Industry

An estimated 5 percent of manufacturing jobs – which equates to approximately 600,000 positions nationwide – are going unfilled due to a lack of qualified candidates, according to the 2011 Skills Gap Report by the Manufacturing Institute. U.S. manufacturers say they are having the hardest time filling key skilled production jobs, such as machinists, operators, craft workers and technicians. In the survey, 67 percent of the more than 1,100 respondents reported a moderate to severe shortage of available, qualified workers, and 56 percent said they anticipate the shortage will grow worse in the next three to five years.

Advanced manufacturing leads patent generation in Iowa

Companies within the advanced manufacturing and associated technologies sector have generated the most patents of any industry group in Iowa in recent years, according to a report prepared for the Iowa Economic Development Authority by the Battelle Technology Partnership Practice. Advanced manufacturing and associated technology companies in Iowa were awarded 4,059 patents between 2005 and 2010, or 78 percent of the 5,192 patents assigned in the state during that period. “Using patents as a surrogate for ‘innovation,’ it is clear that advanced manufacturing and associated technologies are an exceptionally important innovation for Iowa,” the report said.

Top patent recipients in Iowa 2005-2010

Company /# of patents awarded

Deere & Co. 408

Pioneer Hi-Bred International Inc. 388

Rockwell Collins Inc. 273

Stine Seed Farm Inc. 248

Monsanto Technology LLC 191

University of Iowa Research Foundation 122

Iowa State University Research Foundation Inc. 107

Maytag Corp. 102

Fisher Controls International Inc. 87

CNH America LLC 84

Vermeer Manufacturing Co. Inc. 84

Source: Battelle Technology Partnership Practice

Grants available to attend international trade seminars

Want to step up your company’s exporting activity? The Iowa Economic Development Authority has grant money available through several programs to help businesses attend international trade shows.

In October, the Iowa Economic Development Authority received a State Trade and Export Promotion (STEP) grant of $370,258 from the U.S. Small Business Administration (SBA) to use for small business exporting assistance programs. The goal of the STEP initiative is to increase the number of small businesses that are exporting, as well as to increase the value of exports for small businesses that are already exporting.

“There has been quite a bit of interest,” said Lisa Longman, financial assistance administrator for the state’s International Trade Office. To qualify, a company must meet SBA guidelines as a small business and agree to participate in follow-up surveys of its progress nine months and 18 months after the trade show, among other requirements.

To learn more about the STEP grant and how your company can benefit, email international@iowa.gov or contact Lisa Longman at (515) 725-3139.

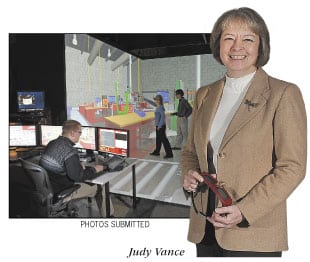

Iowa State’s METaL virtual reality lab provides new research tool

The lab, which cost a little more than $400,000, was built by Marshalltown-based Mechdyne Corp., with support from ISU’s College of Engineering, the Institute for Physical Research and Technology and the department of mechanical engineering. Mechdyne specializes in developing these types of advanced immersive three-dimensional environments.

Inside the lab, a student can walk up to an assembly area on a virtual factory floor and manipulate virtual components, with sensory clues that include metallic clangs. One of the goals of METaL is to spread the use of virtual reality in the manufacturing industry, said Judy Vance, an ISU professor of mechanical engineering. Vance said the lab will be used to study and develop 3-D display techniques, with a focus on building more natural interaction techniques into virtual reality.

“One of the reasons I like to work in this space is the ability to walk up to a virtual image of a 3-D object and explore it from many different angles,” she said. “The aspect of moving in the space makes it more real than standing here and flying towards it.”

Vance said her students recognize the value of virtual reality. “And when they get jobs in industry, they’ll say, ‘We need to do virtual reality.’”